Welding is a core skill for an ironworker, a process that is necessary to join metals and fabricate our built environment and infrastructure. It’s a skill that takes time to learn and lots of experience to master. And even when it’s mastered, there’s the kind of mastery that makes itself visible in perfect conditions: a single waist-high weld, clear and easy access to the joint, on the ground, good weather, maybe even indoors. And then there’s the mastery that delivers quality welds in all the conditions that present themselves on job sites. Hundreds of feet in the air, in a confined space, brutal cold, having minimal access to the weld. The good news is that the Ironworkers Local 512’s apprenticeship program will teach you how to become a master welder, then give you the opportunity to hone those skills until you are one, under any conditions.

Types of welding

While many DIYers are familiar with welding, the type of welding they do is very different from what Ironworkers do. People welding in a shop or school are typically using a GMAW (Gas Metal Arc Welding) process. GMAW is a very user friendly, easy to learn method that you can quickly become proficient at. It uses a weld machine and feeder to deliver a solid or metal cored wire through a weld torch to the joint. The Gas part of GMAW refers to an inert shielding gas used to keep the atmosphere around the weld free from oxygen and nitrogen, two gases that are detrimental to weld quality.

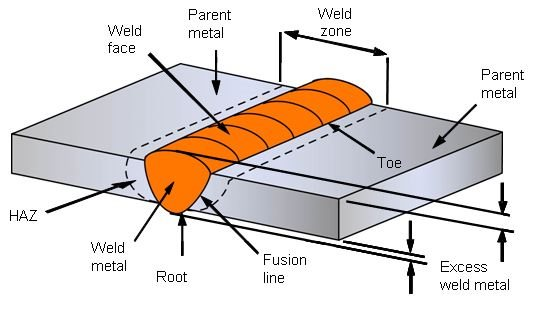

Ironworkers, by contrast, primarily use SMAW (Shielded Metal Arc Welding) or “Stick welding,” as it’s called on the jobsite, and FCAW (Flux Cored Arc Welding), or, to the Ironworker, “Wire.” These processes are much harder to learn and master than GMAW due to the extra variables that come into play. One of the biggest differences in stick welding and wire welding is that they are “self-shielded” processes. No shielding gas is introduced into the process from an exterior source, as is the case with GMAW. That’s primarily because of the nature of Ironwork, which is that it’s mostly done outdoors, where any wind will simply blow away a shielding gas. The gas shielding for Stick/Wire welding comes from compounds in the electrodes themselves, which is why they are self-shielded. Self-shielded welding processes result in a heavy slag on the weld, a protective coating similar to glass that helps shape and cool the weld. Managing the slag, an other variables, is a skill that can take many months to learn and even many years to master.

Types of welds

There are lots of types of welds, but a few of the most common ones to the Ironworker are:

· Puddle weld

This is exactly what it sounds like: a little puddle of molten metal holding things together. Here is one holding down sheet steel decking used to cover a roof.

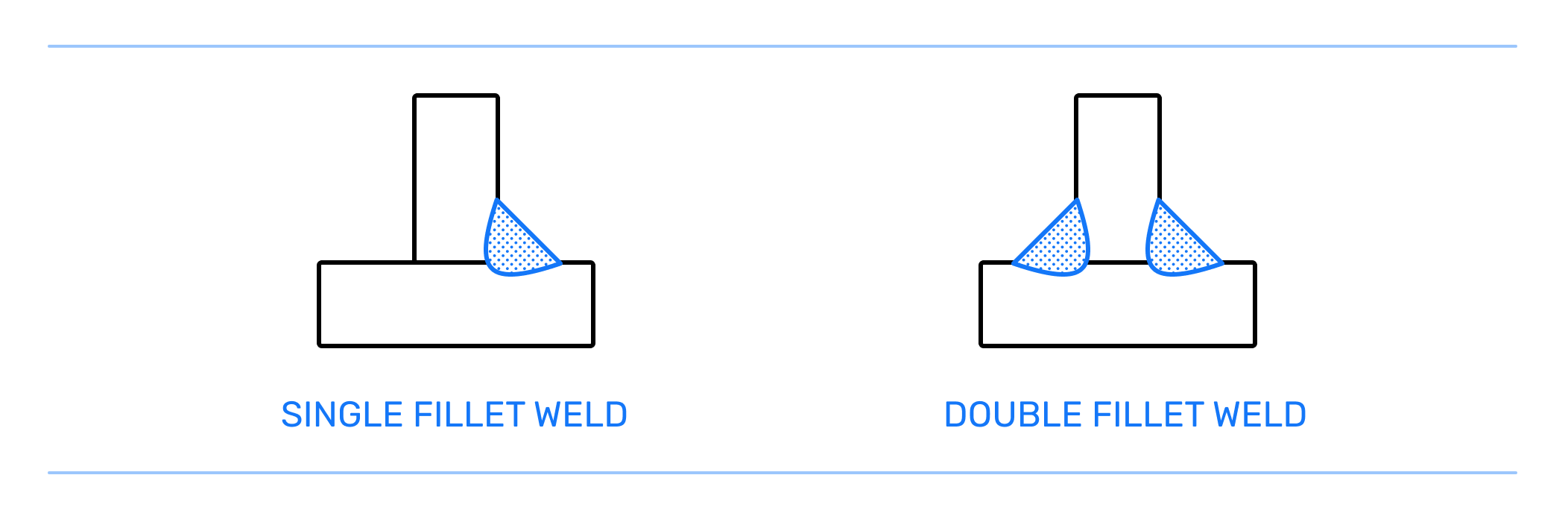

· Fillet weld

These are used in the corner made when two pieces of steel meet, like a T, and binds a vertical piece with a horizontal piece. They are the most common type of weld.

· Groove weld

These are the most complex and difficult of the three types listed here. Groove welds join two pieces of steel through their thickness. There are several types of groove welds that vary in difficulty and complexity, but the simplest type is a butt joint. Butting two pieces together and welding them together throughout their thickness.

Factors that affect Ironworkers’ welds

Beyond the welding process and the type of weld being used, there are many other factors that impact an Ironworker on a jobsite. Joint design, for example, affects weldability. If the design is wider and more open, that’s much easier to weld, but if the joint design is tight due to other constraints, weldability can get much harder. If it is a complete joint penetration with an open root, it will be much harder than if it is the same weld with a backer bar.

Accessibility is another factor. Where is the weld located physically? How easy is it to get to? Once you’re there, how easy is it to reach with the welder? Is the weld on the ground at chest level or is it, to pluck an example out of thin air, 127 feet above ground on the high bank of the roller coaster Wild Thing at Valley Fair, and the only way to reach it is to climb the track?

Obstructions are another major factor. Is there something in the way? Sometimes you have to contort yourself to reach the weld. Other times it’s completely obstructed and the only way to make the weldment is by using a mirror.

How the joint fits together is another factor. Sometimes the pieces of metal don’t line up like they are supposed to. This can pose a real challenge to a welder.

Visual appeal can sideline even the most experienced welders. Every Ironworker is going to do a good quality weld every time, but there’s less pressure to create a perfect-looking weld when you know it’s going to be hidden inside a wall, or buried underground. But if something is part of a show piece that will be highly visible, seen by the masses, then there’s an aesthetic component to consider as well.

These are just a few of the factors that Ironworkers deal with on a regular basis. There are many others, and every weld is different. Something that looks complex and difficult might turn out to be easy with a good plan in place. On the other hand, something that looks routine can become quite challenging when a few of these factors get mixed in. That’s actually one of the best things about Ironwork: every job is different and brings its own set of challenges.

Safety

Welding, with the ultra-bright flame, the heat, and the sparks, can look intimidating, even scary. But with proper training and personal protective equipment, it’s as safe as any other aspect of Ironworking, or the construction trades in general. The Ironworkers Local 512 is committed to safety, and our training is centered around recognizing hazards, preventing them, and making sure that Ironworkers follow the practices that keep them safe.

One last thing along these lines: don’t get sucked in by the welders who do their best work on YouTube instead of on metal. Most of them are self-proclaimed experts and some simply do not know what they are doing. Lots of them have bad habits, and if you don’t know how to spot them, you can pick them up yourself. With an audience always thirsty for a shortcut “tip” or “hack,” the YouTubers’ motivation is to give the audience what they want. And there is no hack to make you a better welder. There’s just training, practice, and discipline. In the end, the only hack is the person you’re watching on screen!

For more information about becoming an Ironworker, visit ironworkers512.com.